CMOS image sensor technology keeps getting better, thanks to new developments. Smartphone makers have been driving demand by making their devices better at taking photos to set them apart from the competition. Moreover, there is a growing market for applications in the security, automotive, manufacturing industries, and medical.

The CMOS Image Sensors test equipment, which works like the retina in our eyes, can now do things that before could only be done with big, expensive cameras. And, compared to smartphones, the new apps make it even more clear that CIS technology needs to be improved.

How CMOS Image Sensor Work

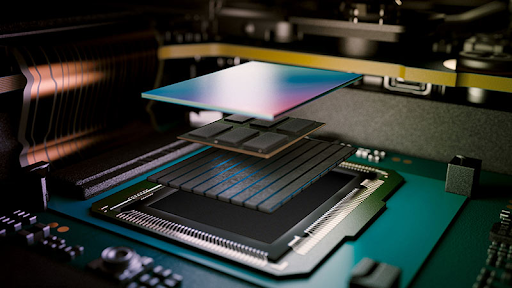

At its most basic level, CIS technology’s job is to turn the light coming through the camera lens transfer into digital data that can be used to make a picture of what’s in view. When the light energy in the visible light wavelength ranges from 400 to 700 nm condenses on the photodiode of the silicon substrate, the surface of a CIS receives the light energy in order to form an electron-hole pair.

Floating diffusion (FD) turns the electrons made by this process into voltage. An analog-to-digital converter then turns the voltage into digital data. The data is sent to a processor, which uses it to make a digital description of what’s in view, which is usually an image.

CMOS Image Sensor Test | What Are Its Techniques

1. Deep Photodiode Formation Process Technology:

Consumers’ constant desire for better image quality has led to a race to improve the number of pixels and resolution in mobile CMOS Image Sensor Test, which has sped up the development of CMOS Image Sensor process technology even more. To get there, the size of the pixels needs to get smaller so that more pixels can fit on the same-sized chip.

2. Pixel to Pixel Isolation Process Technology:

When it comes to high-definition CMOS Image Sensors, the technology to separate pixels from each other is very important. Different isolation technologies are used by chipmakers. Using one that isn’t as well-developed could cause problems with the image, such as colors that mix or spread out.

3. Color Filter Array Process Technology:

Color filter array (CFA) is a process that is only used in the CIS domain. It is not often used in the memory processes for semiconductors. Most of the time, a color filter (CF) and microlens (ML) are used in the CFA process. The color filter separates the light into green, blue, and red for each wavelength range, and the microlens improves the efficiency of condensing. In order to make high-quality images, it’s important to look at R, B, and G color materials and come up with ways to improve thickness and thickness.

4. Water Stacking Process Technology:

Wafer stacking, which means literally putting two wafers together, is a key technology for making products with high-resolution and high-pixel counts. The dimensions of wafer stacking technology, which has been used by the majority of CIS chipmakers, are continuously evolving.

Read Also : PUBG Mobile Midasbuy

5. Control Technology For Quality And CIS Yield:

Metallic contamination management is one of the most fundamental criteria of the CIS mass production and product development process. Since automated test equipment products are several times more vulnerable to contamination than memory products and contamination has a direct impact on product yield and quality, several contamination control technologies are mandatory.

Controlling plasma damage is also an essential concern. Due to the deterioration of image qualities, such as hot pixels, caused by process-related damage, it is vital to regulate key operations correctly.

In Conclusion

It is not an exaggeration to suggest that the process technology will decide the effectiveness of CMOS Image Sensor Test-driven applications. The manner in which these distinct processes interact with one another will also play a significant influence. It is not sufficient to improve a single part of the manufacturing process; all aspects must be optimized to complement one another.